01.04.2021

When it comes to freight transport, digitalisation has a whole grab bag of benefits to offer. It makes transport easier and more efficient. Even smaller-scale technical innovations like digital automatic coupling (DAC) can make a difference. June 2020 saw the beginning of a pilot project commissioned by the German Federal Ministry of Transport and Digital Infrastructure to demonstrate, test and approve digital automatic coupling for rail freight transport. The test phase has been underway since then.

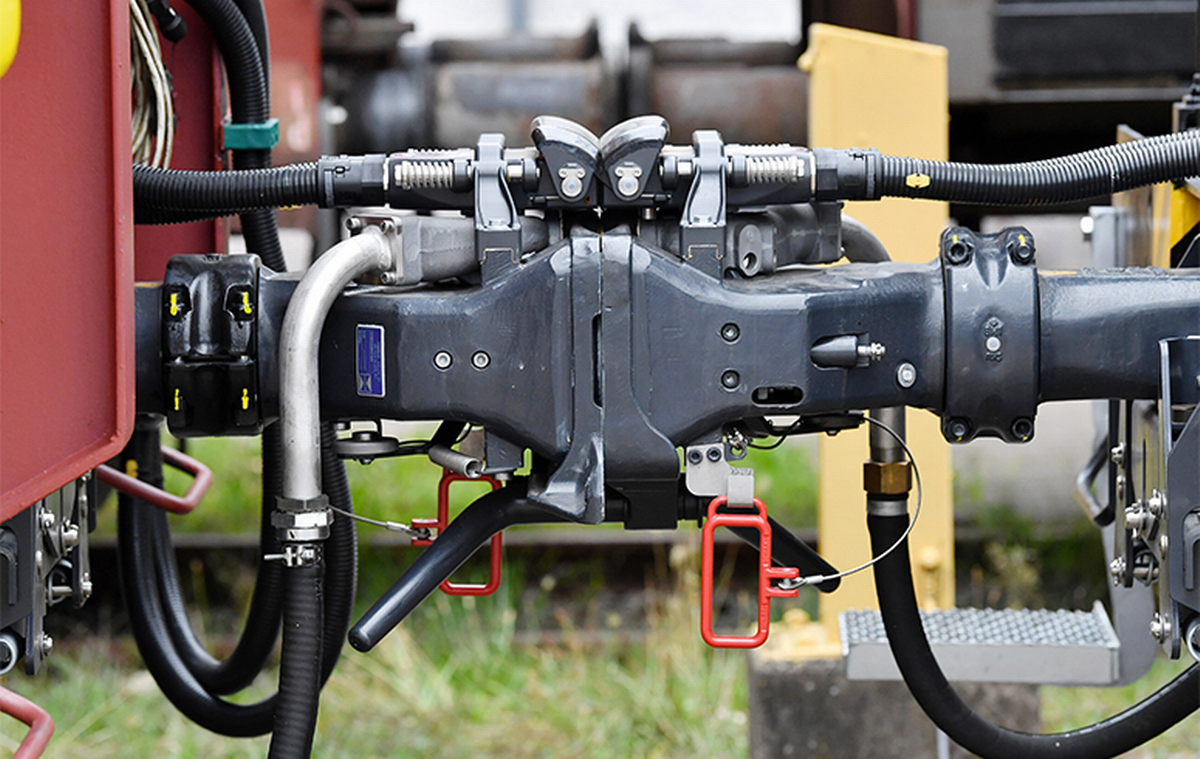

Manual screw couplings are on the fast track to obsolescenceDigital couplers are replacing the screw couplers used in rail freight transport for over 100 years. Coupling and decoupling trains is purely manual with the old couplers. First, a shackle weighing some 20 kg is connected to the hook of the adjacent wagon. Digital automatic coupling automatically couples freight wagons together mechanically allowing for power, data and compressed air lines to be connected end-to-end along the entire length of the train. This cuts down on the manual labour railway employees need to perform. First and foremost, however, DAC makes train formation much quicker. Every day, DB Cargo alone links up some 54,000 wagons in Germany. Counting all of Europe, the daily figure comes to about 400,000 wagon couplings in rail freight operations.Decarbonising the transport sector through faster train formationVarious tests are underway to implement digital coupling, most recently in DB Systemtechnik's climatic chamber in Minden. In the chamber, different types of couplings from different manufacturers (Scharfenberg, SA3 and Schwab) are exposed to temperatures between -25 and +45 degrees. Ulrich Meuser is the project manager for the pilot: "The project is running completely to schedule. To see if the couplings work properly, we need to conduct extensive tests under real-world conditions. We've already clearly shown that digital automatic coupling makes the work of forming freight trains much faster, which in turn considerably boosts on-track capacity." This means DAC can make a real contribution to ensuring that the decarbonisation of transport is a success. The couplings are tested in four temperature ranges – in dry weather, with slush, ice and in extreme, 90% humidity. The results have been pleasing so far. Further tests are scheduled to run in Görlitz and Minden by the end of June. Among other things, the couplings will be tested extensively with various wagon loads and at various speeds on different track radii. On the whole, experts are upbeat about the tests carried out thus far, although they have pointed out some areas that could stand to improve.

Key European project

The DAC4EU consortium (Digital Automatic Coupling for Europe) is the organisation behind the testing of the DAC. It is comprised of seven partners (DB Cargo, Ermewa, GATX Rail Europe, Rail Cargo Austria, SBB Cargo and VTG) under the leadership of DB AG. The project volume now totals around 25 million euros. More information can be found on the project website at www.dac4.eu. The EU transport ministers also plumped for the technology in a statement in Berlin touting DAC as a key project for the European rail freight sector.

The European DAC Delivery Programme (EDDP) will tackle all other issues involved with preparing to deploy DAC jointly in the sector at European level, such as technical specifications, business cases and migration planning.

How digital automatic coupling (DAC) works

DAC automatically connects adjacent freight wagons. In this way, the system creates a mechanical tie between the wagons, and shunting staff do not need to perform any manual work. At the same time, the DAC couples the air lines for the brakes and power and data bus lines; this also happens automatically.