This is how the future works!

A journey to the year 2050.

Often we don’t notice a turning point until we look back. 2020 was one such point, the height of a trend that started with industrialisation and seemed unstoppable by the mid-20th century. It was precisely this year of crisis that laid the foundation for the developments likely to result in absolutely carbon-free and sustainable supply chains and consumption.

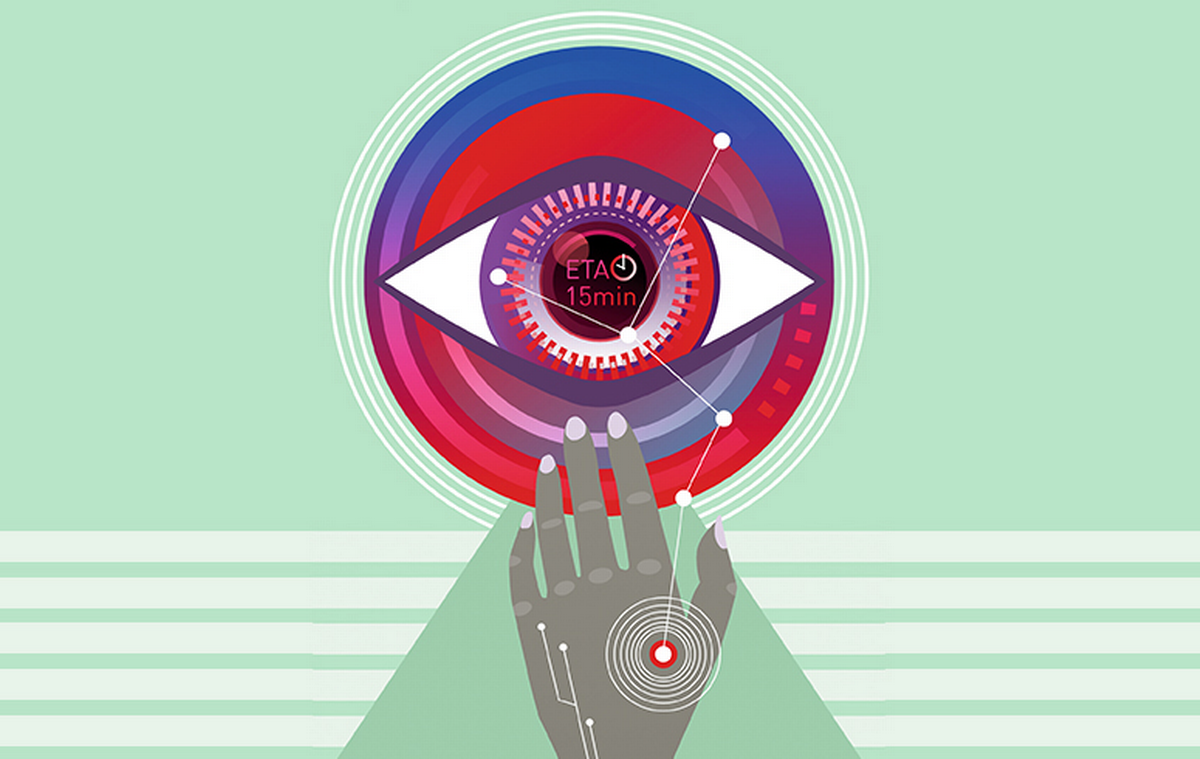

In 2050, no one can say for sure whether it was the pandemic that opened people’s eyes or the Fridays for Future demonstrations that finally yielded results. The fact remains, though, that life has changed radically in the last 30 years because people themselves have changed. Suddenly, living sustainably is more than just the latest hip thing to do — it’s taken deep root in people’s consciousness. Emma doesn’t take it for granted, though. Back in her school days, she took part in the Fridays for Future movement herself.The movement set its sights high, but nobody would have ever believed that one day Greta Thunberg would be the Environment Commissioner of the European Union. In 2050, it is now an EU that truly deserves to be called a community, a union working together to draw up and implement binding decisions for the entire continent. What a difference they made back then! Today, Emma is supply chain manager for logistics at EcoCon, the leading consumer goods group, and is actively helping to shape what she and her fellow campaigners took to the streets for 30 years ago. A gentle vibration on the back of her hand interrupts her thoughts and tugs her out of the past and back to the present — her chip implant is signalling an incoming message. Once she confirms, the message is projected directly onto her iris: "Your DB Cargo shipment is arriving in exactly 15 minutes."

Vegan and carbon-freeAfter all, supply chains in 2050 are not only completely carbon-free; they are also absolutely reliable and accurate to the minute. A comprehensive rethinking of policy was what made this all possible. The major crises of the early 2020s paved the way for the first green German government and even the first green Federal Chancellor. Even more surprising was that almost all the opposition parties suddenly recognized the urgency of the situation and pulled together. Railways were expanded, there was a push to accelerate a clever mix of transport modes, and last but not least, digitalisation was fully embraced and took a giant leap in the mid-2020s. Since then, logistics has been inconceivable without artificial intelligence. Companies like EcoCon reaped the benefits, too; without zero-carbon transport they couldn’t even exist on the market. In addition to sustainable silphium honey, the group offers a selection of purely vegan products. Amid the coronavirus pandemic, even the most die-hard doubters came to realise that factory farming had simply become untenable.

In the future, artificial proteins will enable us to pull staple foods out of 3D printers on demand. Copyright: Mathis Burmeister

From printer to plateThere was already a trend towards vegetarian food back at the turn of the century, though it failed to fully catch on at first. Now it would be unthinkable to practise factory farming or ship and slaughter animals under cruel conditions. It took a while to turn the corner, but 15 years ago EcoCon really found its stride, even manufacturing artificial protein in small regional laboratories. The feat rendered factory farming obsolete in a single stroke, while also significantly reducing the huge swathes of land lost to water-hungry and energy-guzzling farming. In their place, forests were replanted and rivers restored; the climate recovered noticeably. The artificial proteins eventually enabled researchers to churn some staple foods out of a 3D printer. What had already become mainstream in industry by the end of the 2020s went on to revolutionise the consumer goods sector, too. People started transporting things much less and with much more awareness of the environmental impact.

Now, products are transported from laboratory centres to stores exclusively by zero-carbon rail, with most of the lines laid underground. As a result, freight transport was fully decoupled from passenger transport by the end of the 2030s, instantly rendering traffic flows safer and more reliable. This was also due to the automation of all transport. That step was the only way to achieve true efficiency. Since then, errors and accidents have been few and far between, and artificial intelligence has been nearly flawless at planning the massive flows of goods. What’s more, all major cities have dedicated underground rail sidings for distributing supplies. Only more rural areas still need transhipment points; the last mile is served by drones or hydrogen-powered, self-driving lorries, depending on the cargo volume. Emma’s store is fortunately big enough.

More or less in person: Holographic avatars are so real that travelling is almost un necessary. Copyright: Mathis Burmeister

Fully automated delivery in an underground company stationThe locomotive glides into the station with barely a sound and stops with millimetre precision. Emma’s chip vibrates again as she takes the elevator down to the track, but unloading is fully automatic, too. Holograms display data about the delivery: the size and weight, the number of pallets and robots needed for unloading, and the train's departure time. After a quick check and an automated comparison against the order, solar-powered robots unload precisely the quantities that are needed – with absolute exactitude. However, the artificial intelligence doesn’t just calculate how much product Emma’s store goes through in a day. Three decades of machine learning have practically erased the concept of overproduction. Nothing is ever produced that won’t actually be consumed. The resource waste of the 20th century is now finally a thing of the past. Emma watches with satisfaction as the wagons are emptied out and her mechanical colleagues collect and assemble the goods. She observes every step very closely. The technology may be well-engineered, but it still doesn’t hurt for a human give it a random check every now and again. She checks, for example, whether the right quality seals are on the goods. There is one for carbon-free transport and another for fair and environmentally friendly production.

Implantables and biohacking: In 2050, messages will be projected directly onto your retina. Copyright: Mathis Burmeister

Beaming will transform logisticsEmma makes her way home on a bicycle. It’s a very old-fashioned choice, almost nostalgic, with no electrical assistance. Now that there is barely any private transport, city centres have become a paradise for pedestrians and cyclists. Emma lives in a particularly green neighbourhood, where each house facade is planted with algae. It wrings the last bit of CO2 from the atmosphere while also insulating residents from the heat and cold. The front door opens automatically when Emma reaches the entrance. Her daughter Carly is already waiting for her in the kitchen: "At school today we had to separate our own garbage to learn how the robots always do it. Super yucky!" "You don't know how good you have it, Carly," Emma replies with a laugh. Even Emma's mother, who now lives in South Africa but visits the family virtually every day as an avatar, can't supress a smile. "Let me tell you what your mother had to do to save us and the planet when she was your age.

In those days they used to compress the rubbish and drag it halfway through Europe to the incinerator – but at least that meant it didn't end up in some Asian landfill." Carly shakes her head in disbelief – how primitive! Meanwhile, researchers are increasingly talking about breakthroughs and the first tangible successes at beaming. That would totally transform logistics, taking it into the world of information and data logistics. There would be a need and an opportunity to redesign a lot of things from the ground up. Emma, at any rate, likes that idea.