Cities, countries, oceans #4: Zeebrugge in time

DB Cargo Logistics provides climate-friendly transport for new cars from Slovakia to Zeebrugge for Jaguar Land Rover.

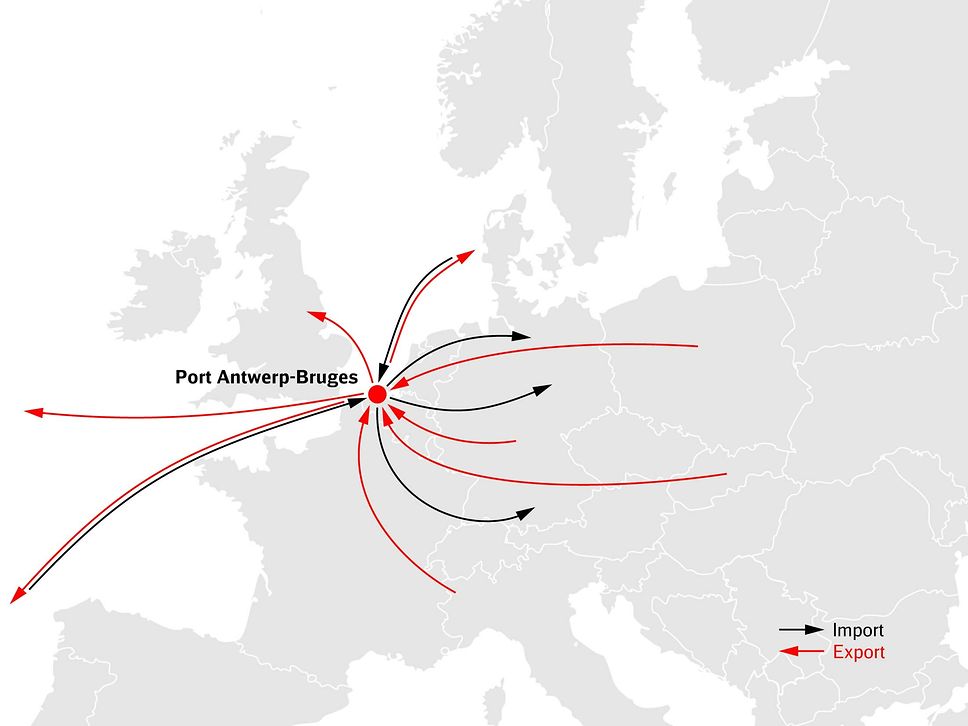

Zeebrugge is the second-largest port in Belgium. It enjoys an ideal location on the North Sea and close to the UK, while at the same time within easy reach of western Europe's economic centres. Zeebrugge is an important container port that can also accommodate deep-draft ships. Above all, it is one of the world's most important transhipment sites for new cars: around 2.2 million vehicles pass through Zeebrugge in an average year.

Flexible handling and super-fast transhipment

It's 2:00 pm. A train from Slovakia is due to arrive at Zeebrugge. It started its journey at the Jaguar Land Rover car plant in Nitra, where around 200 new Defender and Discovery SUVs were loaded onto the train for the journey westwards. From Zeebrugge, they will be routed not just to Great Britain, the USA and Canada, but also to Australia and Oceania. With buyers already waiting for them, they need to get to their destinations as quickly as possible. As the train reaches the unloading ramp, a bus arrives with seven drivers ready to distribute the vehicles to different terminals depending on their destination.

"This is one of the special features that Zeebrugge offers the automotive industry," explains Jurgen de Smet, Head of Commercial Activities at Port Operator CLdN Ports Zeebrugge nv. CLdN Ports Zeebrugge nv, part of the CLdN Group, is one of the largest stevedoring companies in the port of Zeebrugge, operating on 3 terminals and specializes in ro-ro vessel handling and automotive compound services including PDI, ancillary services and vehicle modifications.

"Within the port's premises, our employees are allowed to drive the cars without number plates or completed registration papers. This permits us to take a flexible approach to handling the new cars and enables a super-fast transhipment process." Shipping new vehicles and car parts is one of several key services provided by the port. Zeebrugge can also be used by deep-sea cargo ships and has a large LNG terminal. This diversification makes it less susceptible to economic turmoil. Every year, 50 million tonnes are loaded onto ships at the port, which employs a total of 10,000 people.

Zeebrugge and Antwerp

Careful transport of valuable cargo

Nitra in Slovakia is the site of a state-of-the-art production facility operated by British car manufacturer Jaguar Land Rover (JLR). Covering an area of 300,000 square metres, it has an annual production capacity of 150,000 vehicles. It builds the Land Rover Defender and Discovery models. Many of its finished vehicles make their way to their new owners via Zeebrugge. "The port is ideal for us. It has enough space to park the cars, plus all of the quality certifications we need," explains Leigh Rainsley, purchasing manager at JLR. "And it has an excellent rail infrastructure." That's important because the Defender and Discovery lines travel by train: DB Cargo Logistics takes them from Nitra to Zeebrugge. This protects the high-value cargo while at the same time being environmentally friendly, fast and efficient. "Every week, we run several trains from the JLR plant in Nitra to Zeebrugge," says Sarah Fiore, account manager at DB Cargo Logistics. "Each one transports more than 200 cars. And we could even increase the volume – if the global supply chains are functioning properly," she explains.

Car too big or wagon too small?

Using trains to transport SUVs the size of the new Land Rover Defender is not a matter of course. The company's large, heavy SUVs posed some basic challenges for train operators. The biggest Defender model weighs 3.3 tonnes. Conventional car-carrier wagons simply couldn't handle this class of SUVs. Rainsley and Fiore recall the initial stages of cooperation between JLR and DB Cargo Logistics: "A wagon just wouldn't fit two Defenders on top of each other. This was a major issue." For this reason, an additional step was necessary before the companies achieve their actual goal of moving new cars to Zeebrugge: they had to undertake a joint technical project to design a new type of car carrier. This had to fit under every bridge and get through every bottleneck, be not too heavy but at the same time roomy and robust. That wasn't all: it also had to meet all specifications and restrictions (some of which are very strict) associated with rail routes. And, finally, it had to have enough space and safety features for large Defenders double stacked. "It was a tough engineering brief," says Rainsley. "To me, it is the best example of our successful cooperation with DB Cargo Logistics, and it marked the beginning of a fruitful long-lasting partnership." While the Nitra plant was under construction, DB Cargo Logistics was also working to enhance how the site would operate by creating a design for the plants own siding and rail system. Rainsley says, "This was another element that helped cement our long-term relationship."

Rail is trending as a means of transport.

JLR isn't the only company going with the times: the modal shift is evident all over Zeebrugge. A growing number of logistics companies are opting for efficient and environmentally friendly transport options so they can meet climate targets and avoid blocked roads," de Smet says. Now, DB Cargo Logistics regularly runs trains on the Nitra–Zeebrugge route for JLR, something that really puts the companies' cooperation to the test. Things certainly aren't easy at the moment: challenges like the pandemic, parts shortages, extreme weather, political changes including Brexit and geopolitical issues such as the Ukraine war demand maximum flexibility from the logistics sector. Then there is the comprehensive upgrade of the rail network throughout Europe: ensuring the availability of climate-friendly rail services tomorrow entails putting up with a lot of construction work on the rail network today. This situation also represents a challenge for Fiore and her colleagues. "These factors are good reasons to concentrate on our customers even more, plan even further ahead and remove as many obstacles as possible. Getting to Zeebrugge in time remains our clear goal," she says.

Read more about the history of Zeebrugge

The seaport owes its name to the merchant city of Bruges, which is located in West Flanders around 12 kilometres inland and is connected to Zeebrugge by a canal. Originally, a storm surge in the 12th century created a direct link all the way between the sea and Bruges, which transformed the city into a commercial hub for several centuries. However, this access route silted up over time, and Bruges had lost its importance by the 16th century. It took until the beginning of the 20th century before a harbour was built on the coast itself. This gave a new lease of life to trade and industry in the densely populated region.