Cities, countries, oceans #2: The Emden connection

From rail to river: DB Cargo delivers pulp through the port of Emden

If a seaport lies at the mouth of a large navigable river, then it will become a hub not only for ocean vessels, but also for inland waterway transport. The port of Emden is a prime example of this. It serves as a universal port, where a wide variety of goods are transhipped, and it handles a wide array of logistics-related tasks. This is evident from the portfolio of services offered by the terminal operator Anker Schiffahrts-Gesellschaft, a subsidiary of the Bremen-based Leschaco Group. From export-bound cars to forestry products and services for the offshore industry – the port is all about supreme flexibility. Transhipping different kinds of products comes with a long list of requirements. Currently, the port focusses on the transport of cars and chemical pulp. The port loads pulp onto inland waterway vessels and trains, which transport the product to various paper mills across Europe. This year, Anker Schiffahrt has increased the amount of pulp and paper it tranships by double-digits.

Emden serves as a hub for inland waterway, ocean and island transports

A voyage across the ocean or just a short hop along the river? A wide range of destinations means a heap of challenges.

Hub in Germany's Emsland region

That's because Emden serves as a hub for one of Europe's largest producers of fine and speciality paper, which is located in Dörpen. Seagoing vessels regularly call at Emden's port. They arrive carrying over 600,000 tonnes of chemical pulp each year from Scandinavia and Brazil, the majority of which is shipped to the customer in Dörpen by inland waterway vessel, an eco-friendly means of transport. Additionally, DB Cargo hauls 65,000 tonnes of pulp by rail from eastern Germany. The large bales of pulp are first loaded onto inland waterway vessels at the port before making their way up the River Ems to Dörpen. DB Cargo's empty wagons are then loaded with new pulp to haul. In single wagonload service, these wagons carry an additional 35,000 tonnes of pulp to paper manufacturers across Europe. Jan Remmers is the managing director of Anker in Emden. "Fortunately, we don't have to deal with any shortages of raw materials," he says, referencing the current situation. "We deliver products to the mill in Dörpen quickly and on an ongoing basis. Sometimes we even help with extra deliveries so the Dörpen plant doesn't have to contend with bottlenecks. If we need to, we work in three shifts, which allows us to respond quickly."

Pulp from Scandinavia, Brazil and Germany

Most of the pulp is transported from Scandinavia or Brazil. The vessels used to haul it vary widely in size. Discharging the load from ships arriving from Scandinavia takes about 14 hours, while the much larger ships from Brazil can take up to two-and-a-half days to empty. The ships carry various qualities of pulp in a variety of fibre lengths from their countries of origin. Brazil exports wood pulp from eucalyptus trees, while Scandinavian ships carry fibres made from birch and spruce trees. The pulp manufactured in eastern Germany is made from coniferous trees and transported by rail.

Shared goal to transport more goods by rail

The port of Emden has an excellent geographical location and is well connected to Germany's Ruhr district, among other places. On average, 30 inland waterway vessels and 35 seagoing vessels arrive in and depart from the port of Emden every week. From their office, Jan Remmers and his team have a view of the harbour area and shipping channel. "The view might be the best part of my job," says Remmers with a laugh. "But all joking aside, I consider it a privilege to work at the port. Working as a team to overcome the challenges each day brings, being right alongside goods as they're transhipped – you can't get any closer to logistics than this."

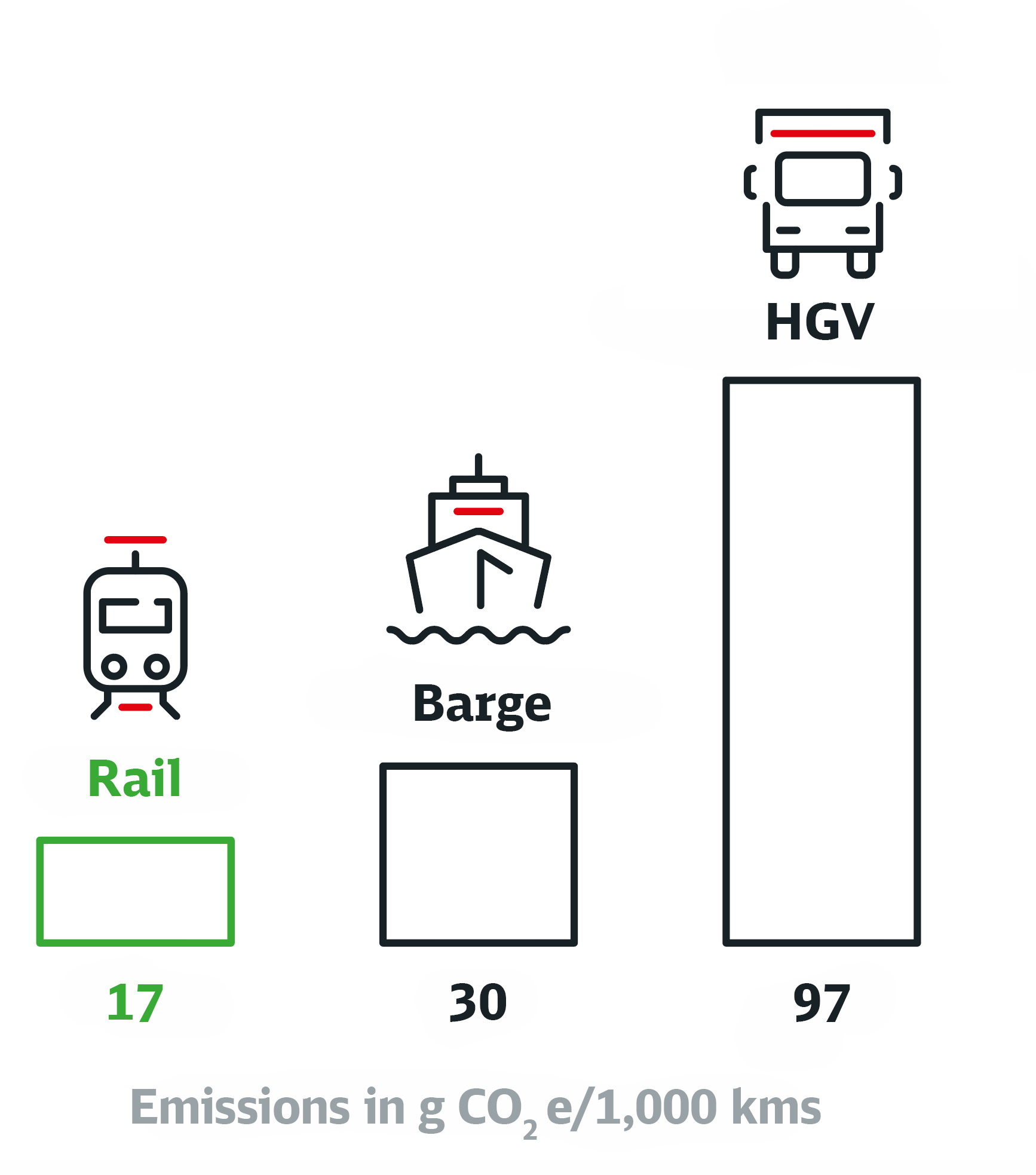

For more than 25 years now, Jan Remmers and his team have worked closely with DB Cargo. Their shared goal is to provide customers with all-in-one packages and to keep shifting more goods to the rails – not least for environmental reasons. "Rail and inland waterway transport are our first choices for long-haul journeys, and not just because of their small carbon footprint," says Remmers. "One inland waterway vessel carries 56 lorry loads and a single rail wagon hauls the equivalent of two and a half lorries. Given the driver shortage we're facing today, those are huge advantages." The port of Emden has 24 usable kilometres of rail and, according to Jan Remmers and his team, the port has considerable potential to offer even more eco-friendly rail freight transports. The port experts agree that a second railway bridge over the Emder Delft, a harbour basin, would be an important addition to ensure rail connections are available for the outer harbour, the automotive plant and island transports. By cleverly linking road haulage and inland waterway transport, the trimodal – or even quadmodal – terminal at the mouth of the Ems could take even better advantage of its strength.