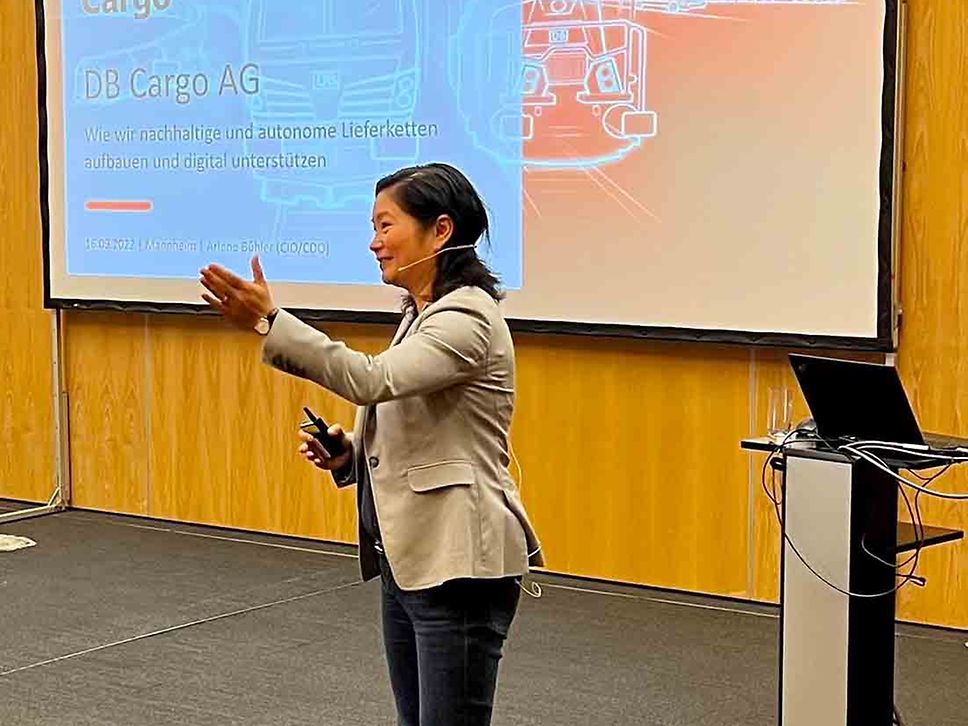

The Bundeskonferenz der Wirtschaftsjunioren, an event for young businesspeople featuring a series of inspiring presentations, took place in Mannheim from 15 to 18 September. At this year's conference, Arlene Bühler, Chief Information Officer (CIO) and Chief Digital Officer (CDO) of DB Cargo, gave a noteworthy presentation on digitalisation in rail freight transport in which she discussed the challenges facing logistics in the future and the solutions DB Cargo is developing to meet them.

Achieving transport decarbonisation through digitalisation

Rail is the logical solution to the challenges of decarbonising both passenger and freight transport. Bühler made this clear right at the beginning of her presentation on how DB Cargo is building and digitally supporting sustainable and autonomous supply chains. Infrastructure is the bottleneck in this process because rail can only be expanded to a limited extent. That means innovative solutions need to be developed to use the existing infrastructure as efficiently as possible. This is where digitalisation and automation come into play. According to Bühler, "they lead us to smart rail freight transport systems" that will get more goods onto trains.

Many parts go into the big picture

Instead of implementing individual and isolated projects, this means looking at the system as a whole in order to put together the best possible overall package for customers and the climate. In her presentation, Bühler named four areas where action needs to be taken: easy customer access, automated train formation, automated train operation and AI to optimise management and planning. "Our goal here is smart freight trains that will be formed at the marshalling yards of the future," said Bühler. This includes many individual measures that, in combination, will enable increased utilisation of the existing infrastructure and faster train formation, which in turn will increase the volume sold in freight transport. See the info box for examples of digitalisation projects.

Selected digitalisation projects

- Fully automatic hump locomotives automate shunting during train splitting, so wagons can be distributed faster

- Smart camera bridges automatically determine the condition of equipment and cargo, and speed up processes at marshalling yards

- Smart freight wagons automatically determine their own condition and identify their cargo, and they always know where they are thanks to GPS

- Digital automatic coupling speeds up coupling of wagons and lines, so trains are ready much faster

- Automated switches help to speed up train formation

According to Bühler, these and other aspects of the digitalisation and automation of process control, tracking and automated train operation will ensure that the main goal of "creating more capacity and getting more goods onto trains" is achieved.