Article: DB CargoLab: Innovation meets tradition

On 3 September 2025, DB Cargo took another important step towards the digital future of rail freight transport in Mainz: with the opening of the new DB CargoLab in the historic Bastion Franziskus, directly at the Mainz headquarters, by Andy Becht, State Secretary in the Rhineland-Palatinate Ministry of Economic Affairs, Transport, Agriculture and Viticulture, Nino Haase, Mayor of Mainz, and Cargo CEO Dr. Sigrid Nikutta, DB Cargo is now pooling its innovative strength at a central location. By using the existing premises at the headquarters, no new office space had to be rented. In this way, DB Cargo not only saves costs, but also acts sustainably.

Focus on digitalization and automation

At DB CargoLab, colleagues from various specialist areas - from engineering, software development and data science to IT architecture and design - work together on forward-looking projects that make rail freight transport more efficient, sustainable and customer-friendly.

Important projects that originated or are being further developed in the DB CargoLab include:

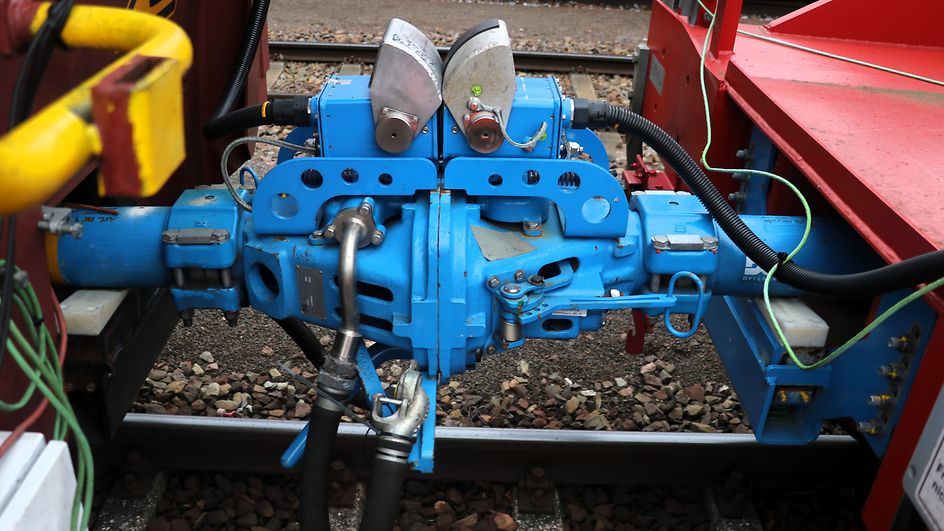

- Digital Automatic Coupling (DAK): still a novelty throughout Europe, this technology revolutionizes the coupling of freight wagons, which was previously a manual and time-consuming process. The DAK automatically connects wagons mechanically and at the same time creates a continuous connection of power, data and compressed air lines. This relieves employees, saves valuable time and increases transport capacities - with positive effects for industry and the environment.

- Intelligent Camera Gates: At eight locations across Germany, this technology automatically records freight wagon damage and analyzes it using artificial intelligence. This allows repairs to be ordered more quickly and in a more targeted manner, which improves wagon availability.

- Distributed Power System (DPS): By remotely controlling a helper locomotive at the end of the train, the train load can be increased by a third - a real efficiency gain for rail freight transport.

- Wagon Intelligence (WI): Thanks to sensors and telematics, over 63,000 networked freight wagons provide data that enables transparent control and optimization of logistics processes. This creates an intelligent basis for digital services and improves customer orientation.

A space for exchange and shaping the future

The DB CargoLab sees itself not only as an innovation workshop, but also as an open meeting place for DB Cargo employees and partners from business and research. Workshops, project work and team days take place here as well as regular professional exchanges on digitalization topics.

Efficient, sustainable, networked

With the new DB CargoLab at the Mainz site, DB Cargo is demonstrating how digitalization and automation go hand in hand to make rail freight transport not only more efficient, but also more sustainable. By using existing rooms at the head office, costs are saved and space is used efficiently - a further step towards sustainable management. Pooling expertise and using state-of-the-art technologies are the key to successfully meeting the challenges of tomorrow's logistics industry.